The rust of the crawling net during use will affect the […]

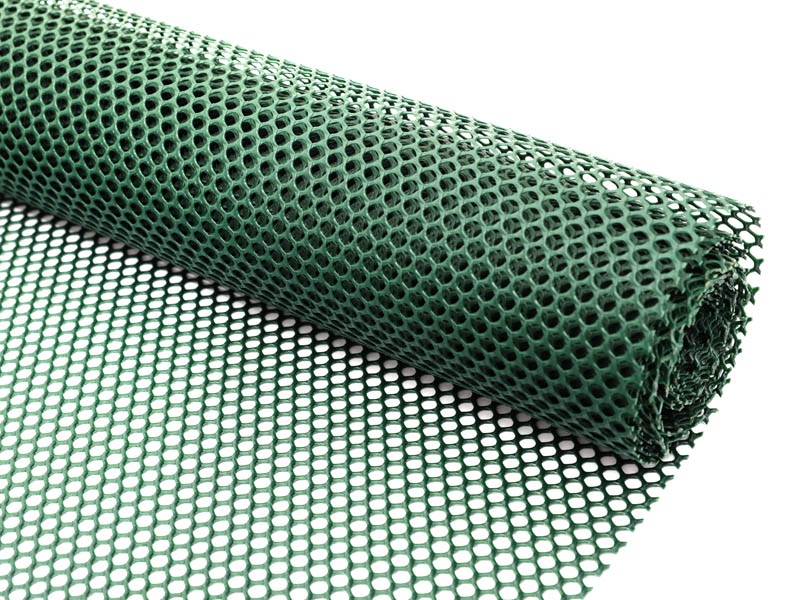

The rust of the crawling net during use will affect the use effect of the crawling net, so how to better prevent the rust of the crawling net and how to clean it after it is rusted?

1. How to prevent the crawling net from rusting

1. Change the internal organizational structure of the crawler. Such as: manufacturing various corrosion-resistant alloys, such as adding chromium to ordinary steel to make stainless steel.

2. The protective layer method is to cover the metal surface with a protective layer to isolate the metal product from the surrounding corrosive medium to prevent corrosion. For example, electroplating, hot-dipping, spraying, etc. are used to coat the surface of steel with a layer of metal that is not easily corroded, such as zinc, tin, chromium, nickel, etc. These metals often form a dense oxide film due to oxidation, which prevents water and air from corroding steel.

Second, the solution after the crawling net is rusted

1. The electrochemical protection method can be used to remove the rust of the perforated mesh, which is to use the principle of the galvanic battery to protect the metal and try to eliminate the galvanic corrosion caused by the galvanic corrosion. Electrochemical protection law is divided into two categories: anode protection and cathodic protection. The cathodic protection method is more widely used. There is also the treatment of corrosive media, which is to eliminate corrosive media, such as frequent cleaning of metal equipment, placing desiccants in precision instruments, and adding a small amount of corrosion inhibitors that can slow down the corrosion rate in corrosive media.

2. There is also a method to remove rust from the climbing net by applying current protection, which is to connect the metal to be protected with the negative pole of the power supply, and choose another conductive inert material to connect with the positive pole of the power supply. After electrification, the accumulation of negative charges is generated on the metal surface, thereby inhibiting the metal from losing electrons and achieving the purpose of protection. This method is mainly used to prevent corrosion of metal equipment in the soil, sea water and river water.

www.chinanetlon.com

WhatsApp:+8613626888261

WhatsApp:+8613626888261